Planning excellence is the lever for a cost-optimized supply chain alignment

Restrained market development and structural changes in the traditionally important customer industries pose great challenges for companies in the metal industry. The smaller the opportunities on the sales side are, the more important it is to look inwards – cost efficiency is key!

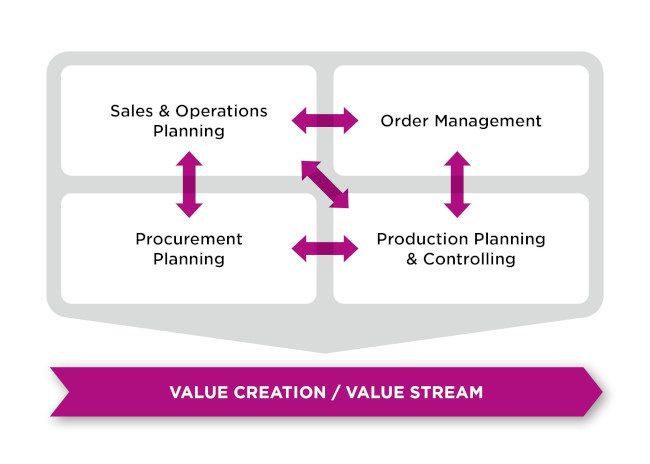

Excellence in planning and control processes is a necessary condition for keeping costs under control along the supply chain. To achieve this, the processes need to be fully interconnected, as this is the only way to make planning decisions with the highest possible transparency, speed and minimum amount of work.

The B&C approach to developing excellence in planning focuses on the integration of the relevant planning and control processes across all planning levels. The aim is to establish robust and reliable planning processes that enable active cost management in day-to-day business and at the same time support the strategic reorientation of the company.

For a costoptimized alignment of the supply chain, structural shifts in demand, such as those currently occurring on the customer side, have to be registered and processed in Sales & Operations Planning. The basis for these planning processes is high-quality sales planning that considers market trends, political developments, etc. With a well-structured process and high-performance IT support, all input data is prepared, possible scenarios are created and thus a basis for decision-making is available for the operational plan. For example, it is possible to assess how the (temporary) shutdown of aggregates, individual production routes or entire sites and thus the bundling of residual demand on the most cost-efficient plants will affect the operating result of the company and its delivery capability. The reallocation of material flows in the network also offers the opportunity to reduce inventories at various stages of the value chain and thus has a positive impact on cash flow.